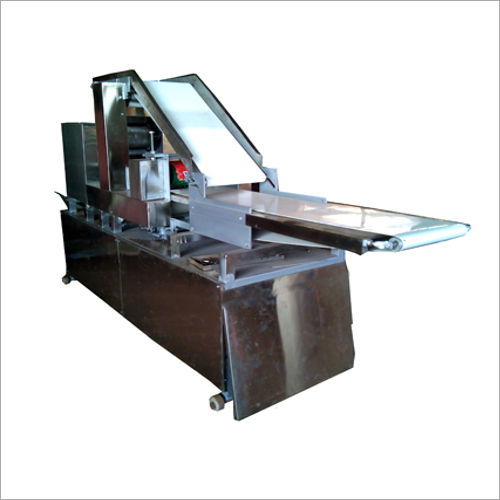

Automatic Poori Making Machine

Product Details:

- Product Type Automatic Poori Making Machine

- General Use Commercial Use, Industrial Kitchens, Food Processing Units

- Material Stainless Steel

- Type Fully Automatic

- Capacity 1000-1200 Pooris/Hour

- Weight (kg) 250 kg

- Product Thickness 1-3 mm (Adjustable)

- Click to View more

Automatic Poori Making Machine Product Specifications

- Automatic Poori Making Machine

- Round

- Commercial Use, Industrial Kitchens, Food Processing Units

- High Efficiency, Low Maintenance, Hygienic Operation

- Optional

- 1-3 mm (Adjustable)

- Yes

- Stainless Steel

- 220-240 V

- Electric or Gas

- Fully Automatic

- 250 kg

- 1800 mm x 700 mm x 1300 mm

- 1000-1200 Pooris/Hour

- No

- Silver

Automatic Poori Making Machine Trade Information

- Bihar, Punjab, Delhi, Haryana, Himachal Pradesh, Rajasthan, Uttar Pradesh, Uttarakhand

Product Description

Our company is devotedly involved in offering Automatic Poori Making Machine. The offered machine is performance based and has high tensile strength. We just need to fed dough into the hopper and at the outlet one gets raw poori. Further, this is checked on different parameters to ensure that we are delivering only flawless machine. This Automatic Poori Making Machine gives oil free, hygienic puri at economical prices. Apart from that, endless PVC food grade belt is mounted on stainless steel covered fabricated angle stand.

Product details

|

Color |

Silver |

|

Material |

Stainless Steel |

|

Usage |

Commercial |

|

Power Required |

Yes |

|

Phase |

Single Phase/Three Phase |

|

Capacity |

1500,5000,10000,15000,20000 Poori per hour |

|

Brand |

Gurpreet Engineering Work |

Automatic High-Volume Poori Production

Engineered for efficiency, this fully automatic machine streamlines production by rolling and frying up to 1000-1200 pooris per hour. Designed for commercial use, it offers programmable thickness and uniform round shapes, reducing manual labor and ensuring output consistency.

Advanced Hygiene and Safety Features

Fitted with a food-grade conveyor, a digital control panel with emergency stop, and heavy-duty stainless steel construction, the machine prioritizes safety and hygiene. Its minimal oil usage and automatic oil spraying system keep operations clean while maintaining product quality.

User-Friendly Operation with Easy Maintenance

The machine features removable parts for hassle-free cleaning and maintenance. Its floor-mounted design is space-efficient, and the noise level remains low, making it suitable for busy kitchens. High uptime and low power consumption enhance operational returns.

FAQs of Automatic Poori Making Machine:

Q: How does the automatic poori making machine maintain hygienic production?

A: The machine uses a food-grade conveyor belt and stainless steel components, minimizing contamination risks. With an automatic oil spraying system and minimal manual intervention, it ensures consistent, sanitary production in compliance with food safety standards.Q: What is the production capacity and can it be adjusted for different poori thicknesses?

A: This machine can produce between 1000 and 1200 pooris per hour. The thickness of each poori is adjustable within a range of 13 mm, allowing customization based on specific requirements.Q: When should the integrated fryer attachment be used?

A: The integrated fryer is an optional attachment designed for kitchens or processing setups seeking an end-to-end frying solution. It is ideal when immediate, automated frying of pooris is required for streamlined operations.Q: Where is installation of this machine recommended?

A: Given its floor-mounted design and robust build, the machine is best suited for commercial kitchens, industrial food processing units, and large-scale catering operations demanding high efficiency and output.Q: What is the cleaning and maintenance process for this machine?

A: Removable parts allow for quick and easy cleaning. Regular maintenance such as checking the oil spraying system and ensuring the conveyor is clean will keep the machine running efficiently and hygienically.Q: How does the digital control panel enhance operational safety?

A: The user-friendly digital control panel features an emergency stop button, enabling immediate shutdown in case of emergencies to maximize operator safety while simplifying machine operation.Q: What are the primary benefits of using this automatic poori making machine?

A: Major benefits include high productivity, consistent product quality, low operational noise, minimal oil usage, hygienic operation, quick cleaning, and reduced labor costsmaking it ideal for high-demand Food Service businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+